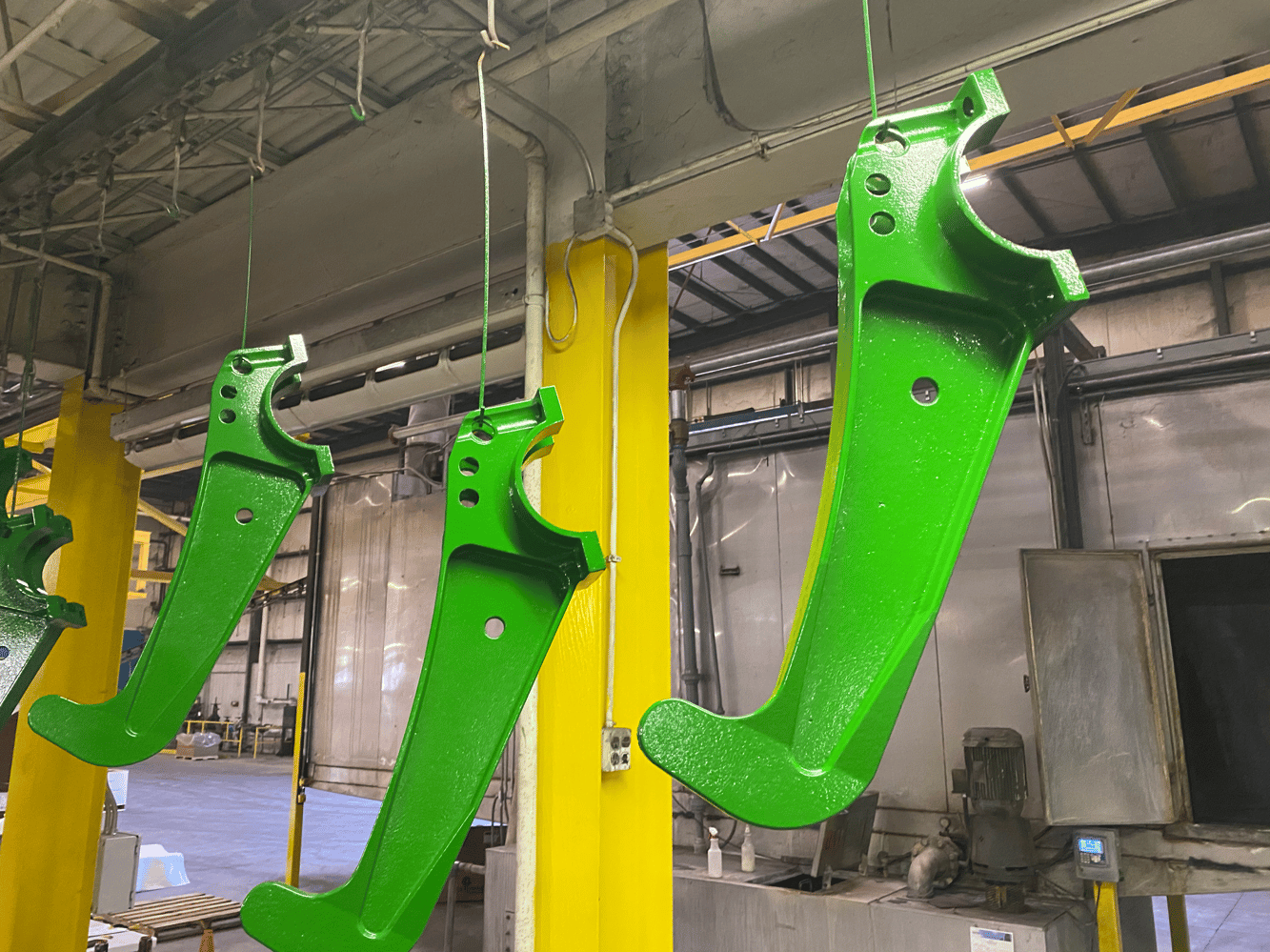

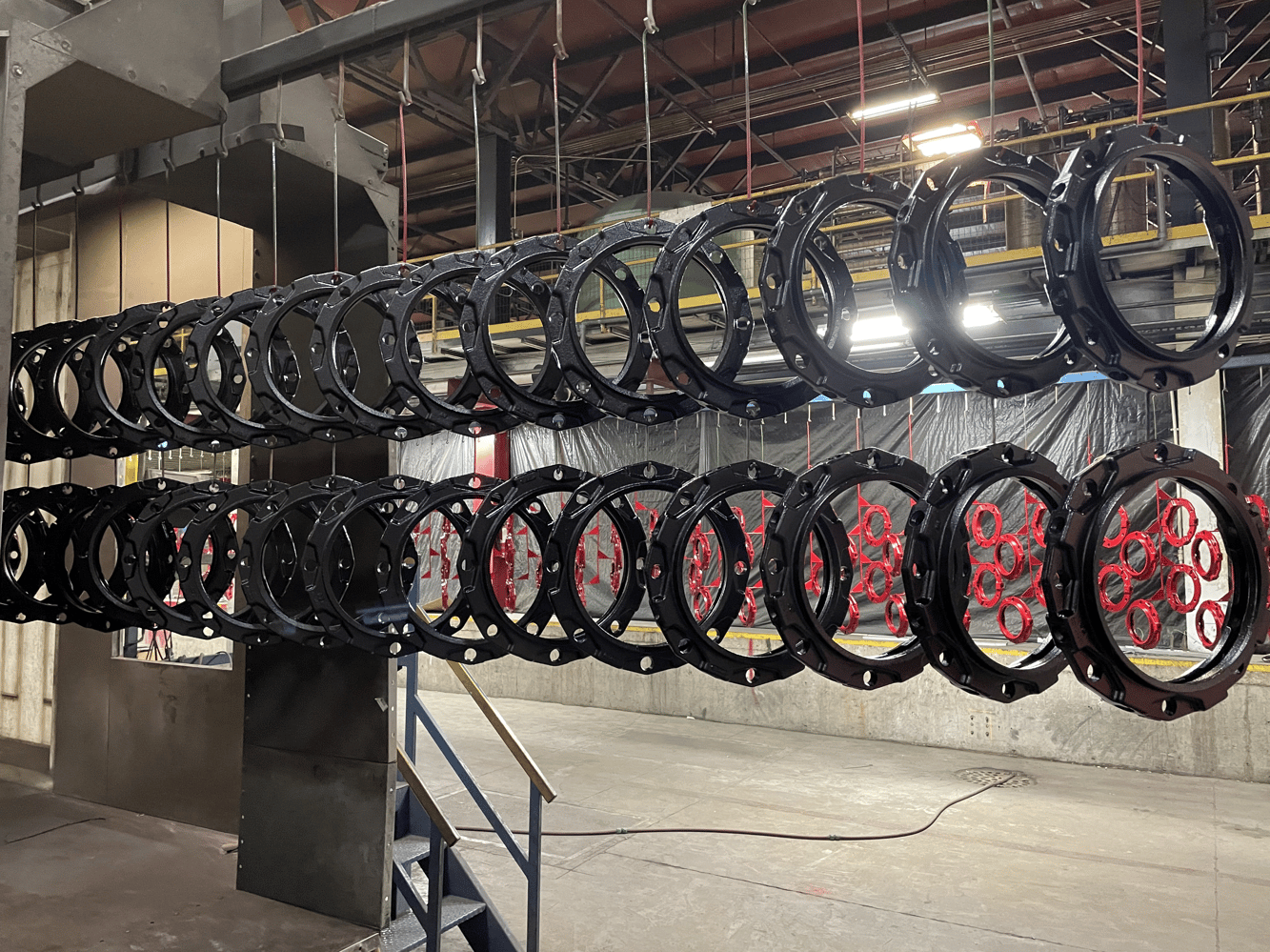

CASTINGS

Winona Powder Coating is THE powder coating choice for so many castings outfits; and for good reason. Not many powder coaters offer the Winona Combination-

-

A conveyorized line for heavy-duty castings featuring our new and much-improved/more efficient GEMA spray booth. This for superior powder application, quicker color changes and clean-up along with much-reduced powder waste.

-

A straight-through 700’ long cure oven for improved efficiencies. The lack of curves leads to no hot and cold spots; something of key importance to getting it right with coating heavy-duty castings.

-

Heavy-duty castings put out a lot of heat. Line Two at Winona Powder Coating offers a long-traversing 1200’ of cool-down area.

-

We are expert in the coating of large and/or heavy castings, depending on part profile. And can provide immediate feedback to our capabilities to finish demanding parts. Just send us a drawing!

-

We stock over 50 different powders to match specific color and environmental needs for our foundry customers.

-

We use low-cure powders so cycles are completed at lower temperatures. Something important for quality castings coating.

-

We are one of the only companies that offer both powder coating and e-coating services.

-

Winona Powder Coating is a PRODUCTS FINISHING magazine’s TOP SHOP award winner four years running (2020, 2021, 2022, 2023).

Foundry operators know powder coating is superior to conventional paint options in many ways, including improved machinability. Our foundry customers also appreciate a finish that is wear and weather resistant and also easy to maintain. In addition to that and other features, it is more environmentally conscious than conventional options because it doesn’t use harsh chemical solvents.

Winona Powder Coating. The growing choice in the heavy-duty castings industry.