EV COMPONENTS

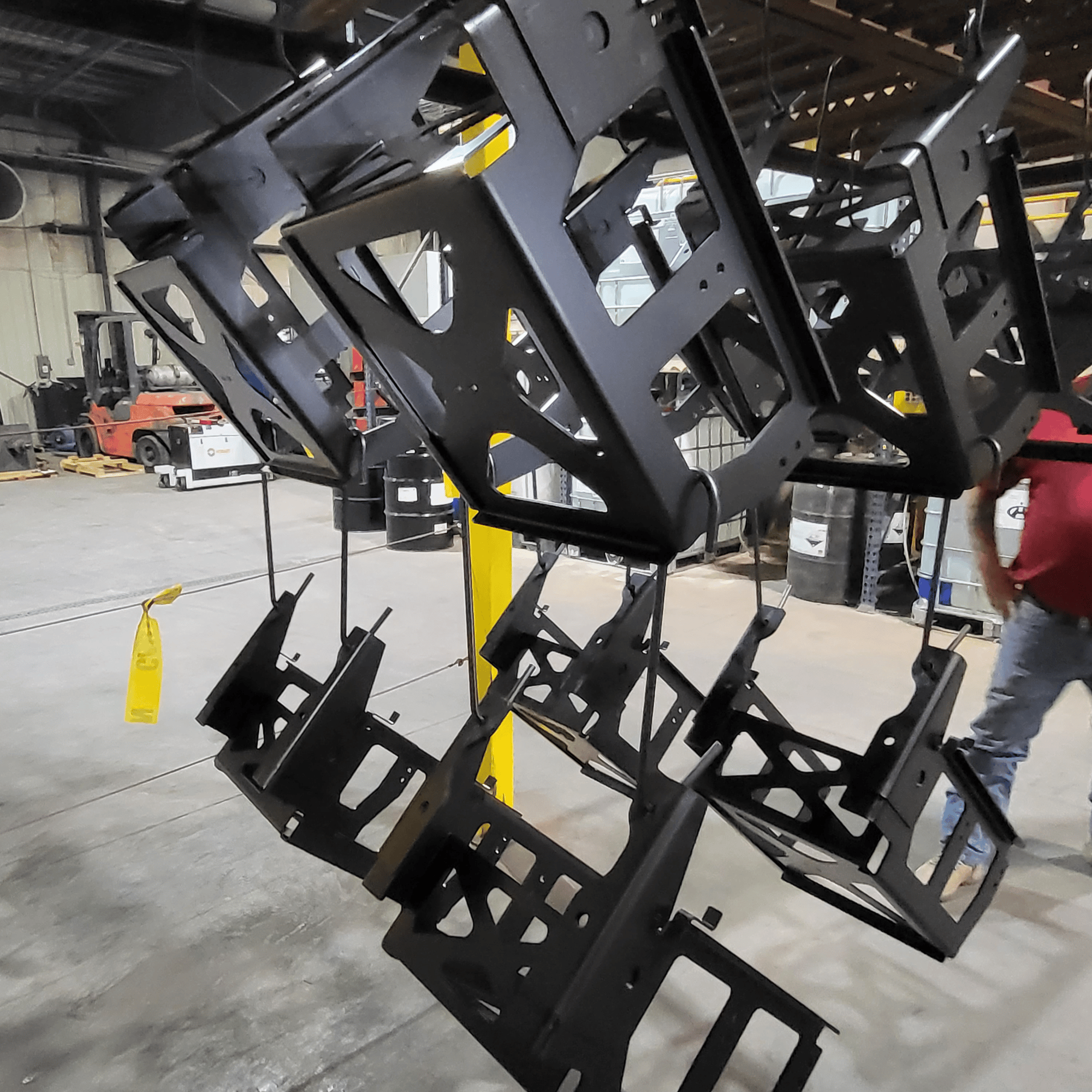

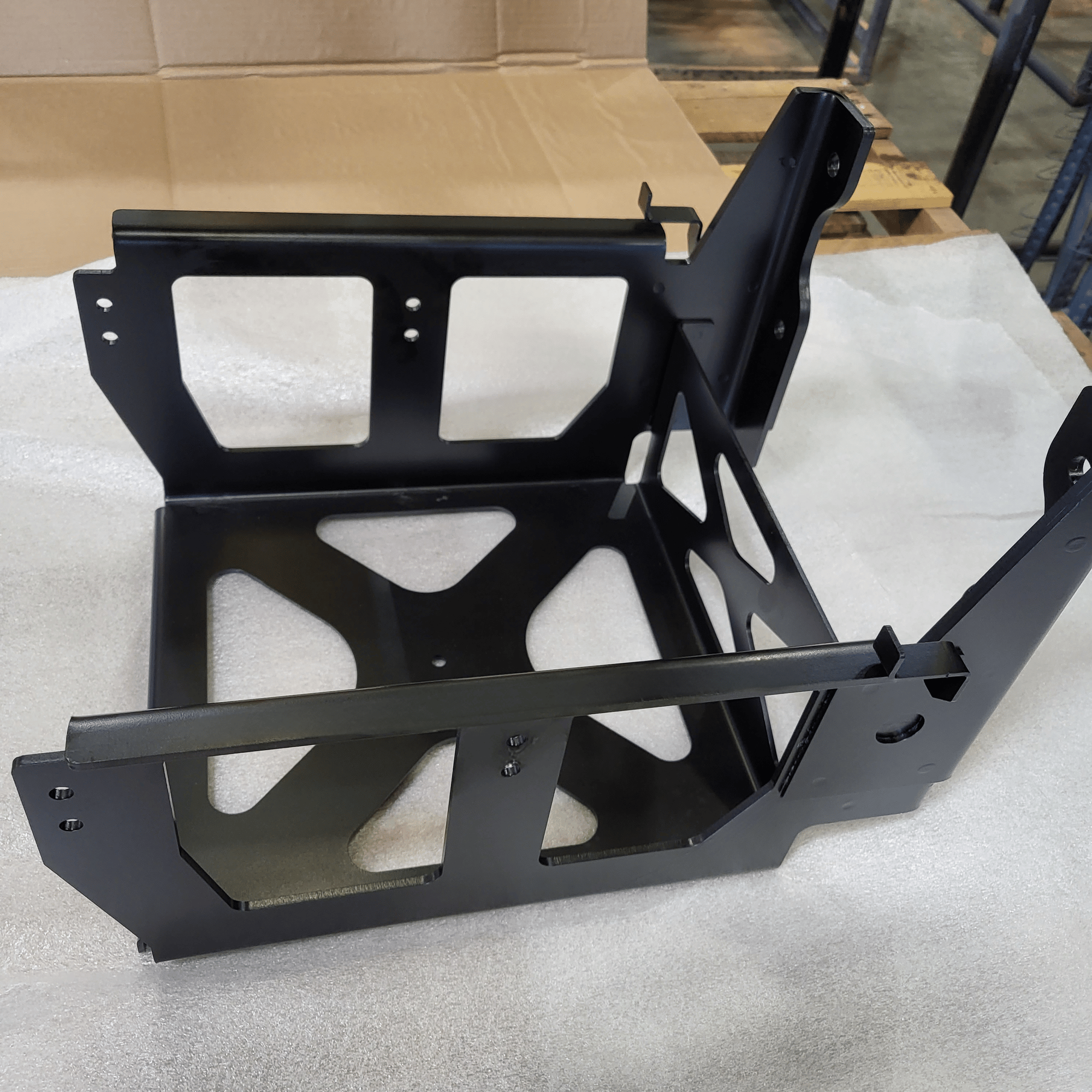

Winona offers three options to protect your EV components from any harsh environment.

- Liquid epoxy electro-coat was originally designed as a corrosion barrier for automotive under- body components. The liquid application insures 100% of the surface area of the part is covered. The epoxy composition provides robust corrosion protection. Our e-coat process passes 1000 hour salt spray exposure even at thicknesses as low as .6 MILS.

- Winona operates three state-of-the-art powder coating lines that are designed to coat most substrates including Cold and Hot rolled steel, Iron and Aluminum. Powder coating offers numerous options in color and composition sure to meet any demand. Coating thicknesses are in the 2 to 5 MIL range and offer a strong protective barrier to corrosion in any environment.

- The ultimate protection from corrosion utilizes an e-coat primer coupled with a powder top-coat. The strengths of both technologies combine to provide the best corrosion protection from even the harshest environments. Our two-part process is the best protection available on the market today.

Winona Powder Coating offers any of these options under one roof. That’s hard to find. And we offer quick turnaround. See how quickly we can get your projects completed.

UL Certified coating supplier for electrical components. We finish a wide variety of products for suppliers to VW, Stellantis, GM, Ford and Jeep among others.